Nti Boilers Troubleshooting : Proven Techniques for Efficient Problem Solving

For NTI boiler troubleshooting, check the thermostat settings and inspect for any leaks immediately. Proper maintenance ensures efficient performance.

When it comes to troubleshooting NTI boilers, addressing issues promptly can prevent further damage and extend the lifespan of your equipment. By being proactive in detecting and resolving problems, you can avoid costly repairs down the line. Regularly checking your NTI boiler for any irregularities and following the manufacturer’s maintenance guidelines will help keep your system running smoothly.

Maintaining your boiler can also improve energy efficiency and lower utility costs in the long run. It is essential to know the common troubleshooting steps to keep your NTI boiler in optimal condition and prevent disruptions to your home’s heating system.

Common Nti Boiler Issues

Nti boilers troubleshooting may include common issues like thermostat malfunctions, low water pressure, and faulty pilot lights. These problems can lead to inefficiency and heating disruptions, requiring professional diagnosis and repairs for optimal boiler performance. Regular maintenance and timely troubleshooting can prevent major breakdowns.

No Heat Or Hot Water

Strange Boiler Noises

Pressure Loss

Nti boilers are a reliable heating solution, but like any system, they can encounter issues. Let’s explore some common problems that may arise with Nti boilers:

When your Nti boiler runs into problems, it can be frustrating. Here are some key issues you may encounter:

| Issue | Description |

|---|---|

| No Heat or Hot Water | Boiler not producing heat or hot water. |

| Strange Boiler Noises | Unusual sounds coming from the boiler system. |

| Pressure Loss | Drop in boiler pressure affecting performance. |

No Heat Or Hot Water

If your Nti boiler is not providing heat or hot water, it could be due to issues with the thermostat, pilot light, or a faulty pump.

Strange Boiler Noises

Unusual noises from your boiler such as banging or whistling could indicate air in the system, trapped water, or a faulty heat exchanger.

Pressure Loss

A drop in boiler pressure can lead to inefficiency. Check for leaks, bleeding the radiators, or repressurizing the system to resolve this issue.

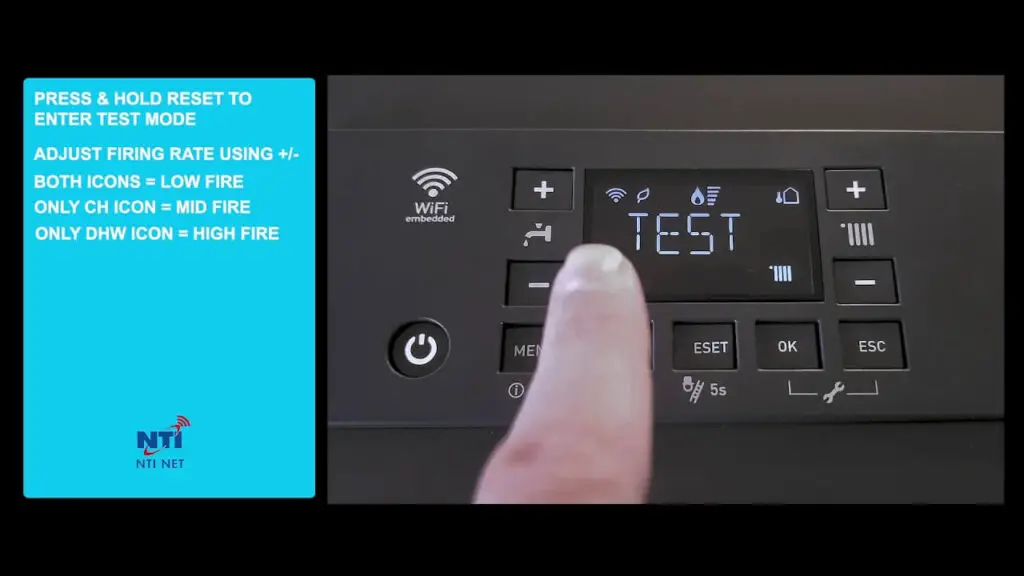

Troubleshooting Techniques

Checking Thermostat Settings

Ensure the thermostat is set correctly.

Inspecting For Air In The System

Ensure there is no air trapped in the system.

Investigating Water Pressure

Check the water pressure to identify any issues.

Preventive Maintenance Tips

Maintaining your NTI boiler through regular preventive measures is crucial to ensure its optimal performance. By executing a series of preventive maintenance tasks, you can avoid potential breakdowns and prolong the lifespan of your boiler. Below are some preventive maintenance tips to keep your NTI boiler running smoothly.

Regular Boiler Inspections

Regular inspections are essential to identify and address any potential issues with your NTI boiler. Schedule professional inspections at least once a year to check for leaks, corrosion, and overall functionality. Properly functioning boilers ensure efficient heating and lower energy costs.

Proper Ventilation Check

Inspect the ventilation system regularly to prevent blockages and ensure proper airflow. Blocked vents or air intakes could lead to combustion issues, causing the boiler to operate inefficiently, or even pose a safety hazard. Keep the ventilation system clear and free from obstructions to maintain the boiler’s efficiency.

Cleaning And Flushing The System

Regular cleaning and flushing of the boiler system are essential to remove built-up debris, sediments, and mineral deposits. These impurities can affect the efficiency of the boiler and lead to potential damage. A clean boiler system ensures optimal performance and reduces the risk of costly repairs.

Professional Assistance

While it’s great to troubleshoot and fix minor issues with your NTI boiler yourself, there are times when you may need to seek professional help. Some problems can be more complex or require technical knowledge that is best left to an expert. In this section, we will explore when you should consider contacting a professional for assistance with your NTI boiler troubleshooting.

When To Seek Professional Help

If you encounter any of the following issues, it’s advisable to reach out to a qualified technician to assess and address the problem:

- Malfunctioning controls that are affecting your boiler’s performance.

- Frequent and recurring error codes that you can’t resolve on your own.

- Unusual noises or vibrations coming from the boiler.

- Major leaks or water damage around the boiler or in its piping system.

- Persistent issues with your boiler’s ignition or burner.

Choosing The Right Technician

When it comes to hiring a technician for your NTI boiler troubleshooting, it’s essential to choose someone who is experienced and knowledgeable in working with NTI boilers. Consider the following factors when making your decision:

- Look for technicians who are certified or authorized by NTI to work on their boilers. These professionals will have the necessary expertise and training.

- Read reviews and testimonials from previous customers to gauge the technician’s reputation and level of customer satisfaction.

- Compare prices from different technicians to ensure you are getting a fair and competitive rate for the service.

- Ask for referrals from friends, family, or neighbors who have had successful experiences with NTI boiler technicians.

Remember, choosing the right technician can make a significant difference in the efficiency and longevity of your NTI boiler. Investing in professional assistance will not only ensure the accurate diagnosis and resolution of issues but also provide you with peace of mind.

Final Thoughts And Recommendations

When it comes to troubleshooting Nti Boilers, it’s important to remember that timely repairs and regular maintenance are key to ensuring optimal performance and longevity of your heating system. In this section, we will discuss the importance of timely repairs and implementing regular maintenance, both of which play a crucial role in keeping your Nti Boiler running smoothly.

Importance Of Timely Repairs

Timely repairs are essential for preventing small issues from turning into major problems that can disrupt your daily life. Ignoring even minor signs of trouble with your Nti Boiler can lead to more significant and costly issues down the line. By addressing problems promptly, you can save yourself from expensive repairs and potential safety hazards.

Regularly inspect your Nti Boiler for any signs of leaks, strange noises, or unusual odors. If you notice any of these indicators, it’s crucial to take immediate action. Contact a professional technician who specializes in Nti Boiler repairs to diagnose and fix the issue. Remember, addressing problems early can prevent further damage to your system and ensure reliable heating throughout the year.

Implementing Regular Maintenance

Regular maintenance is an integral part of keeping your Nti Boiler in top shape and avoiding unexpected breakdowns. By scheduling routine maintenance, you can identify and address any potential issues before they become major problems. This proactive approach can save you from experiencing inconvenient and costly breakdowns, especially during the peak heating season.

During the maintenance check, a qualified technician will inspect and clean various components of your Nti Boiler, ensuring they are functioning efficiently. They will also check for any signs of wear and tear that may require repairs. Additionally, the technician will perform important tasks such as flushing out the system, testing safety controls, and inspecting fuel lines to ensure that your Nti Boiler is operating safely and effectively.

To avoid forgetting your maintenance schedule, consider setting up a reminder or working with a professional who offers annual service contracts. These contracts often include routine maintenance visits, priority service, and discounts on repairs, providing you with peace of mind and helping you save on overall boiler maintenance costs.

In conclusion, taking prompt action when troubleshooting your Nti Boiler, along with implementing regular maintenance, will help you maintain a reliable and efficient heating system. By addressing any issues promptly and staying proactive with maintenance, you can ensure the smooth operation of your Nti Boiler for years to come.

Frequently Asked Questions For Nti Boilers Troubleshooting

Why Is My Nti Boiler Not Turning On?

Check if the power supply is connected and if the thermostat is set correctly.

How Can I Fix A Leaking Nti Boiler?

Inspect the leaking area, tighten any loose connections, and consider calling a professional for repairs.

Why Is My Nti Boiler Making Strange Noises?

Noises may indicate air in the system, low water pressure, or a faulty pump. Schedule a maintenance check.

How Often Should I Service My Nti Boiler?

It is recommended to have your boiler serviced annually to ensure optimal performance and prevent potential issues.

What Does Error Code “e001” On My Nti Boiler Mean?

Error code “E001” typically indicates a flame detection problem. Contact a qualified technician for troubleshooting and repairs.

Conclusion

Troubleshooting Nti boilers can be manageable with the right knowledge and tools. By following the provided tips and techniques, you can effectively address common boiler issues and ensure efficient functionality. Remember to conduct regular maintenance to prevent potential problems and seek professional assistance when needed.

With these insights, you can confidently manage Nti boiler troubleshooting efficiently.